CG MATERIAL

Spherical Tantalum Powder

Spherical Tantalum Powder

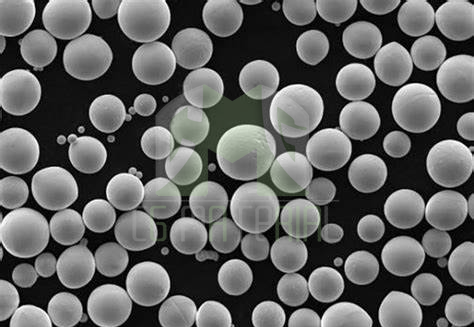

Spherical Tantalum Powder is a high-purity, fine-grained powder made up of spherical particles of tantalum metal. It is produced using advanced powder metallurgy techniques such as gas atomization and plasma spheroidization, which result in a uniform particle size distribution and a high degree of sphericity.

Spherical Tantalum Powder Specifications

| Chemical Formula | Ta |

| Shape | Spherical Powder |

| Particle Size | 5-25μm, 15-45μm, 15-53μm, 45-105μm, 75-150μm, customized |

| Purity: | 99%-99.99% |

Spherical Tantalum Powder Datesheet

| Chemical Composition | ||||

| Element | Content (%) | Element | Content (%) | |

| Mg | <0.005 | W | <0.01 | |

| Cu | <0.001 | Ni | <0.005 | |

| Fe | <0.005 | Cr | <0.005 | |

| Ti | <0.005 | Si | <0.005 | |

| Mn | <0.001 | Nb | <0.005 | |

| Mo | <0.005 | Ta | 99.95% | |

| Gas Impurities | ||||

| Element | Content (%) | Element | Content (%) | |

| C | <0.005 | O | <0.1 | |

| N | <0.01 | |||

Spherical Tantalum Powder Applications

Spherical Tantalum powder can be used in sputtering targets, alloys, thermal and chemical resistant coating, 3D printing (additive manufacturing), and electrolytic capacitors. There are four types of powders:

- Nodular powder from the chemical reduction of tantalum salt or oxide. The resulting powder is aggregated consisting of primary particles and pores. It has a relatively low density and high surface area.

- EB powder from hydride and de-hydride of electron bean or arc melted ingot. The particle of this powder is typically angular and non-aggregated.

- Capacitor Grades powder can be used to manufacture high-performance chip or dipping-type tantalum electrolyte capacitors.

- Spherical powder from plasma inert gas atomization. This generates a spherical shape with a smooth surface that has excellent flow characteristics. The powder is particularly suitable for 3D printing.

Spherical Tantalum Powder Characteristics

High purity (≥99.9%)

low oxygen (≤300ppm)

high sphericity (≥98%)

smooth surface

no satellite spheres

uniform particle size distribution

excellent flow properties (≤6.0s/50g),

high bulk density (≥9.5g/cm3) and tap density (≥10.5g/cm3).

Packaging

Standard Packing: Vacuum-sealed in foil bags, 500g/bag to 5 kg/bag. Iron drums lined with a plastic bag, 25 kg/drum.Special package is available on request.