CG MATERIAL

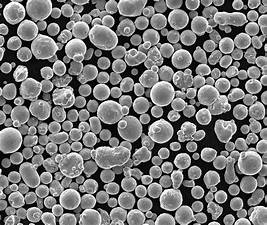

Spherical Inconel 939 Powder For Additive Manufacturing and Thermal Spary

Spherical Inconel 939 Powder For Additive Manufacturing and Thermal Spary

Specifications

| Main Chemical Compositions | Ni, Cr, Co |

| Shape | Spherical Powder |

| Particle Size | 15-45μm, 15-53μm, 45-75μm, 45-105μm, 75-150μm, customized |

| Appearance |

Grey powder |

DataSheet

| Element | Percentage (%) | Element | Percentage (%) |

| Ni | Balance | Nb | 1.4-1.8 |

| Cr | 22.0-23.0 | Fe | 1.0 max |

| Co | 18.0-21.0 | C | 0.15-0.17 |

| Mo | 0.4-0.6 | Si | 0.5 max |

| W | 1.4-1.8 | Mn | 0.5 max |

| Al | 1.4-1.8 | P | 0.015 max |

| Ti | 3.6-4.2 | S | 0.015 max |

Properties:

Properties:

- Density: ~8.14 g/cm³

- Melting Point: ~1,365°C (2,489°F)

- Oxidation Resistance: Excellent resistance to oxidation at high temperatures

- Thermal Stability: Maintains strength and creep resistance at temperatures up to 900°C (1652°F)

- Corrosion Resistance: Excellent resistance to hot gas corrosion and oxidation

- Mechanical Strength: High tensile strength and creep rupture properties, even at elevated temperatures

Key Benefits of CG Material's Spherical Inconel 939 Powder:

- High Temperature Strength: Maintains mechanical properties at elevated temperatures, providing strength and stability in demanding applications.

- Oxidation and Corrosion Resistance: Resistant to oxidation and corrosion in high-temperature environments, making it ideal for gas turbine and combustion engine applications.

- Flowability and Uniformity: The spherical shape of the powder ensures excellent flow characteristics, crucial for 3D printing and thermal spray coating processes.

- Creep Resistance: Exceptional creep rupture strength under high-stress conditions.

Handling and Safety:

- Inhalation Risk: Fine Inconel 939 powder particles can be hazardous if inhaled. Always use personal protective equipment, such as masks and gloves, and ensure proper ventilation in the workspace.

- Storage: Store the powder in a dry, airtight container to prevent oxidation and contamination.