CG MATERIAL

Spherical Inconel 718 Powder (UNS N07718) For Additive Manufacturing and Thermal Spary

Spherical Inconel 718 Powder (UNS N07718) For Additive Manufacturing and Thermal Spary

Specifications

| Main Chemical Compositions | Ni, Cr, Fe, Nb |

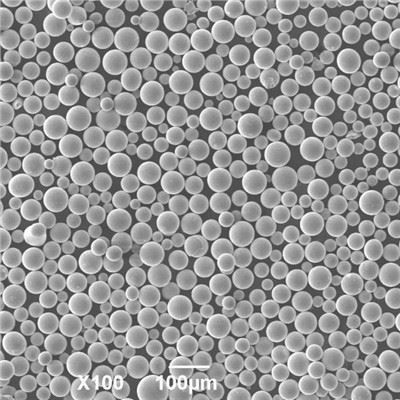

| Shape | Spherical Powder |

| Particle Size | Customized |

| Appearance | Silver powder |

Datasheet

| Ni (%) | Cr (%) | Fe (%) | Mo (%) | Nb (%) |

| 50-55 | 17-21 | Balance | 2.80-3.30 | 4.75-5.50 |

| Ti (%) | Al (%) | Co (%) | Si (%) | Mn (%) |

| 0.65-1.15 | 0.20-0.80 | <1.0 | <0.35 | <0.35 |

Mechanical Properties (Typical at Room Temperature):

- Tensile Strength: ~1370 MPa

- Yield Strength: ~1030 MPa

- Elongation at Break: ~12-25%

- Hardness (Rockwell C): ~30-40 HRC (depending on heat treatment)

Heat Treatment:

Spherical Inconel 718 powder components can undergo heat treatments for enhanced mechanical properties:

- Solution Annealing: Typically performed at 980-1010°C, followed by rapid cooling.

- Aging: Performed in stages, such as 720°C and 620°C, to precipitate strengthening phases (γ′ and γ″).

Advantages of CG Material's Spherical Inconel 718 Powder:

- Excellent Flowability: CG material provides powder to ensure excellent flow characteristics, crucial for 3D printing and powder bed fusion processes.

- High Packing Density: Spherical particles offer better packing density, leading to stronger, more uniform printed parts.

- Outstanding Corrosion and Oxidation Resistance: Ideal for applications in harsh chemical environments and high temperatures.

- Versatile Use: Can be processed by various methods such as additive manufacturing, thermal spraying, and powder metallurgy.

Handling and Safety:

- Inhalation Risk: Fine metal powders, including Inconel 718, can be hazardous if inhaled. Proper ventilation and personal protective equipment (PPE) should be used when handling the powder.

- Storage: Store in a dry, controlled environment to prevent contamination and oxidation. The powder should be kept in airtight containers to ensure its quality is maintained.