CG MATERIAL

Spherical Inconel 713C Powder (UNS N07713) For Additive Manufacturing and Thermal Spary

Spherical Inconel 713C Powder (UNS N07713) For Additive Manufacturing and Thermal Spary

Specifications

| Main Chemical Compositions | Ni, Cr, Al, Mo |

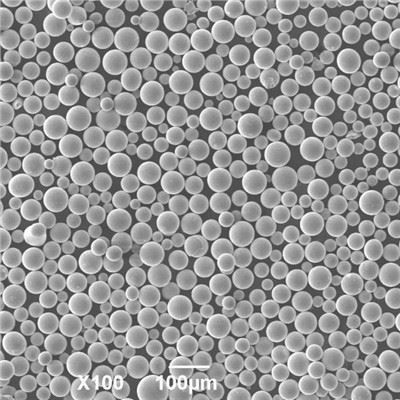

| Shape | Spherical Powder |

| Particle Size | 15-45μm, 15-53μm, 45-105μm, 75-150μm, customized |

| Appearance | Grey powder |

DataSheet

| Element | Percentage (%) | Element | Percentage (%) |

| Ni | 70.0 - 76.0 | C | 0.08 - 0.20 |

| Cr | 12.0 - 14.0 | Co | ≤ 0.20 |

| Al | 5.5 - 6.5 | Fe | ≤ 0.50 |

| Mo | 4.0 - 5.0 | Si | ≤ 0.50 |

| Ti | 0.6 - 1.1 | S | ≤ 0.015 |

| Zr | 0.05 - 0.15 | B | 0.005 - 0.010 |

Applications:

- Additive Manufacturing (3D Printing): Spherical Inconel 713C powder is used in metal additive manufacturing processes like SLM and EBM to produce complex, high-performance parts with precision.

- Thermal Spraying: The powder can be applied as a protective coating to components operating in high-temperature environments, improving resistance to wear, oxidation, and thermal fatigue.

- Metal Injection Molding (MIM): The powder's fine particle size and spherical shape make it ideal for injection molding, enabling the production of complex shapes with good mechanical properties and minimal post-processing.

Handling and Safety:

- Inhalation Risk: Fine metal powders can pose respiratory hazards. Proper protective equipment, such as gloves, masks, and goggles, should be used during handling.

- Storage: Should be stored in airtight containers to avoid contamination and oxidation.

Please contact us for quotation !