CG MATERIAL

Boron Nitride Composite BN-AlN Ceramic

Boron Nitride Composite BN-AlN Ceramic

Boron Nitride Composite BN-AlN Ceramic is a type of high-performance ceramic material that is made from a combination of boron nitride (BN) and aluminum nitride (AlN) powders. It is produced through a high-temperature and high-pressure sintering process, resulting in a ceramic material with exceptional thermal and mechanical properties.

BN-AlN ceramic has a unique combination of high thermal conductivity, high electrical insulation, and excellent mechanical strength, making it a highly desirable material for a variety of industrial and electronic applications.

The addition of aluminum nitride to boron nitride creates a composite material with enhanced thermal conductivity, improved mechanical strength, and increased resistance to thermal shock. The combination of these properties makes BN-AlN ceramic ideal for use in high-temperature applications, such as heat exchangers, high-temperature furnaces, and electronic packaging.

BN-AlN ceramic is also highly resistant to chemical attack, making it an ideal material for use in harsh environments. Its exceptional electrical insulation properties make it a popular choice for electronic components, high-voltage insulators, and other electrical applications.

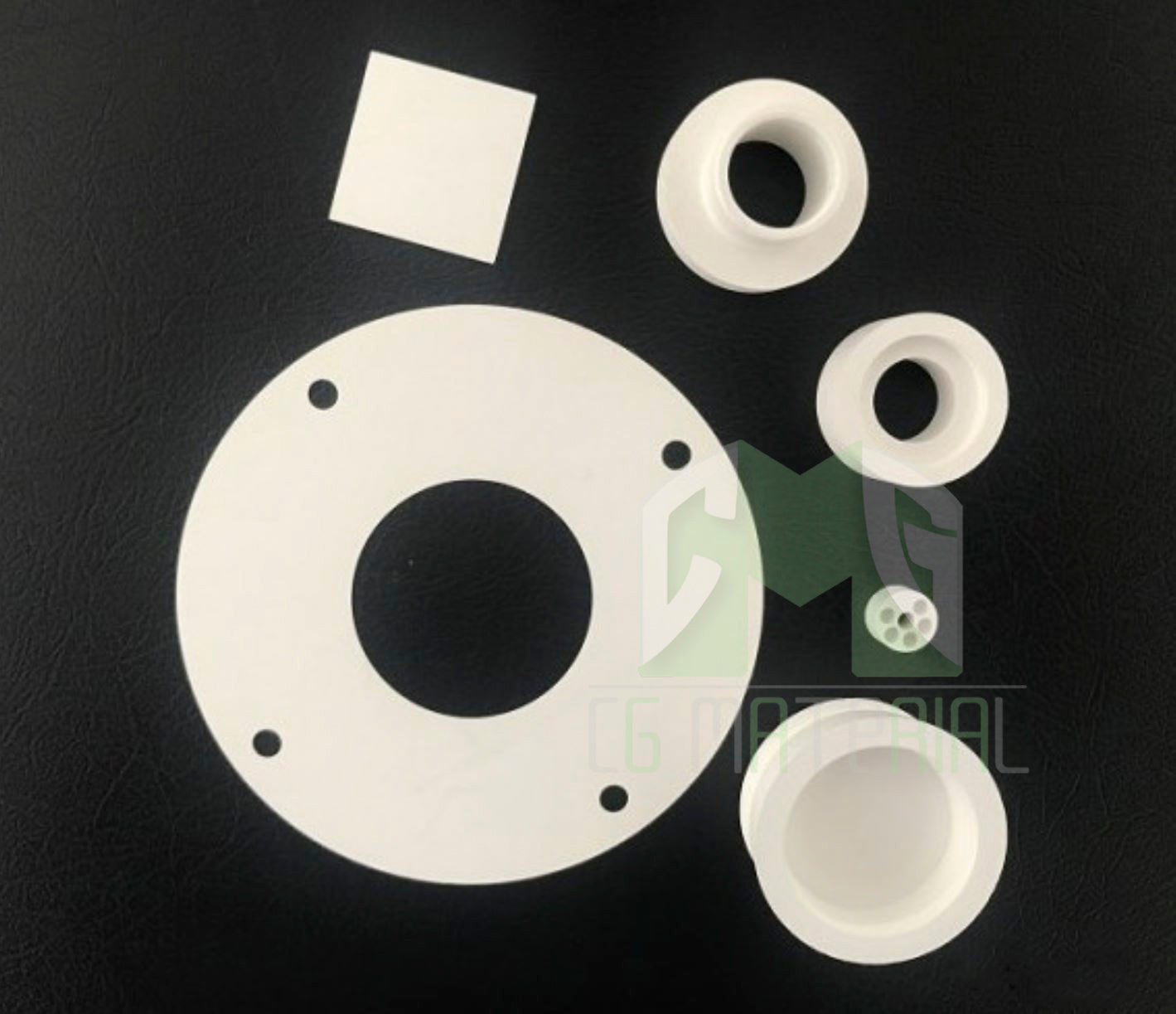

BN-AlN ceramic is available in a range of shapes and sizes, including plates, tubes, and custom shapes. Its properties make it a versatile material that is used in industries such as aerospace, semiconductor manufacturing, metallurgy, and automotive manufacturing.

Boron Nitride Ceramics Specification

CG Material production formulations are developed to address the varied application problems in which ceramic components are commonly used. Many industrial applications push the envelope on specific requirements leading to the development of new formulations to successfully address them.

| Item No. | Description | Purity | Lot Size |

| CG-NI05-98 | Boron Nitride Powder Particle Size: 3 µm, 200 mesh or 325mesh |

BN > 98 %, B2O3 < 0.6%, Ca < 0.015%, Si < 0.12% |

100 kg 1000kg Customize |

| CG-NI05-99 | Boron Nitride Powder Particle Size: 3 µm, 200 mesh or 325mesh |

BN > 99 %, B2O3 < 0.4%, Ca < 0.01%, Si < 0.10% |

100 kg 1000kg Customize |

Comparison of Boron Nitride Ceramics

| Grade | BN-BO | BN-SZ | BN-AlN |

| Compositions | BN>98% | BN+SiC+ZrO2 | BN+AIN |

| Binder | B2O3 | / | AlBO3 |

| Density | 2.1-2.2 g/cm3 | 2.3-3.0 g/cm3 | 2.5-2.6 g/cm3 |

| 25°C Volume Resistivity | >1013 Ω·cm | >1012 Ω·cm | >1014 Ω·cm |

| Max. Service Temp. (°C) Oxygen; Inert Gas; High Vacuum |

900 2000 1800 |

900 1700 1700 |

900 2100 1900 |

| Flexural Strength | 75 Mpa | 100 Mpa | 130 Mpa |

| Compressive Strength | 100 Mpa | 300 Mpa | 250 Mpa |

| Coefficient of Thermal Expansion 25-1000°C |

2.0 x 10–6/K | 4.0 x 10–6/K | 4.5 x 10–6/K |

| Thermal Conductivity | 30 W/mK | 40 W/mK | 60 W/mK |

Composite Ceramic BN-AlN Specifications

| Grade | BN-AlN |

| Compositions | BN+AIN |

| Binder | AlBO3 |

| Density | 2.5-2.6 g/cm3 |

| 25°C Volume Resistivity | >1014 Ω·cm |

| Max. Service Temp. (°C) | 900 (Oxygen) |

| 2100 (Inert Gas) | |

| 1900 (High Vacuum) | |

| Flexural Strength | 130 Mpa |

| Compressive Strength | 250 Mpa |

| Coefficient of Thermal Expansion (25-1000°C) | 4.5 10-6/K |

| Thermal Conductivity | 60 W/mK |

Composite BN-AlN Ceramic Applications

• Insulation

• Semiconductor equipment components

• Molded glass fixture material

• Used as bearings and gears

Packaging

We handle our products with care to ensure they remain in their original condition during storage and transportation and to preserve their quality.