CG MATERIAL

Aluminium Magnesium Master Alloy Al-Mg Alloy

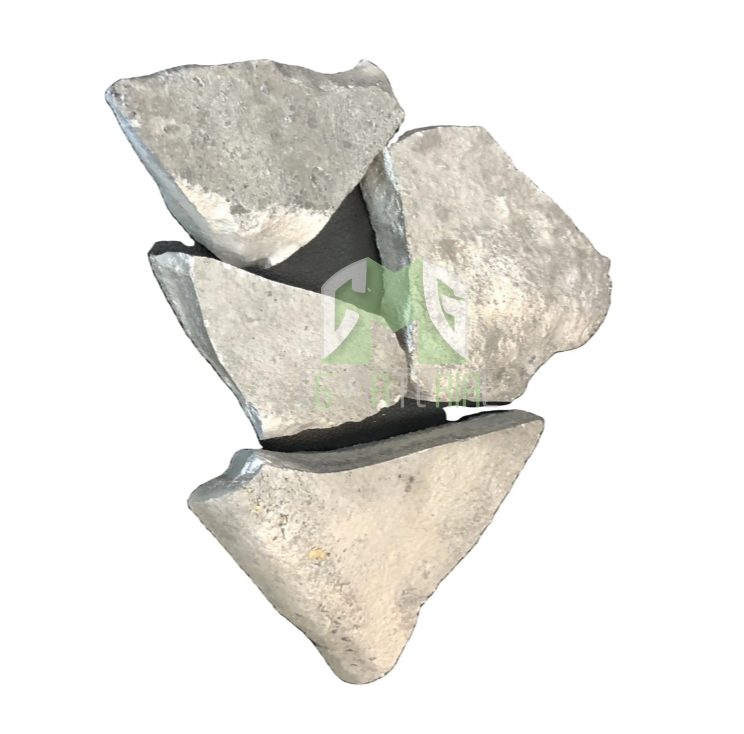

Aluminium Magnesium Master Alloy Al-Mg Alloy

| Compositions | Aluminum, Magnesium |

| Content | Mg 5%-50%, Al Balance |

| Shape | Lump, Ingots, Waffle ingot, Customized Shape |

Overview

Aluminum-magnesium master alloys are semi-finished materials available in various shapes. These pre-alloyed mixtures of alloying elements—often referred to as modifiers, hardeners, or grain refiners depending on their function—are added to molten metal to achieve specific metallurgical properties. Compared to using pure metals, master alloys offer a more cost-effective solution, reducing both energy consumption and production time.

Applications

-

Aluminum casting alloys (e.g., Al-Si-Mg, Al-Mg alloys)

-

Wrought aluminum alloys (5xxx and 6xxx series)

-

Automotive and aerospace structures requiring good strength-to-weight ratios

-

Marine applications due to improved corrosion resistance

Handling Considerations

-

Mg is highly reactive; using a master alloy minimizes oxidation losses.

-

Proper fluxes or inert gas coverage may be used during melting to prevent oxidation.

Packing

Aluminum-magnesium master alloys are packaged in steel or fiber drums, wooden or cardboard pallet boxes, and securely stretch-wrapped on pallets. Most products are kept in stock to ensure prompt delivery.