CG MATERIAL

Boron Nitride Custom Machined Parts (H-BN)

Boron Nitride Custom Machined Parts (H-BN)

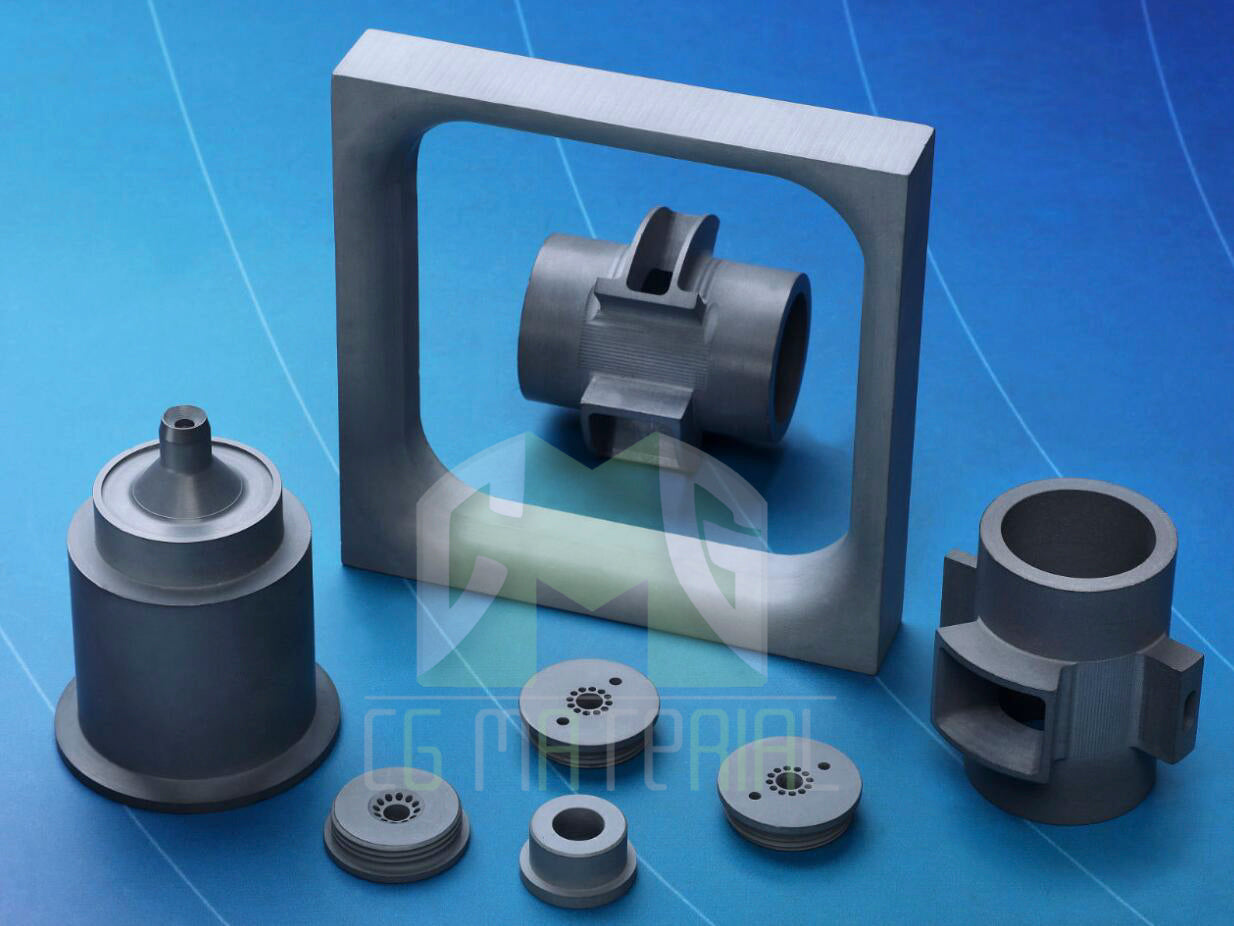

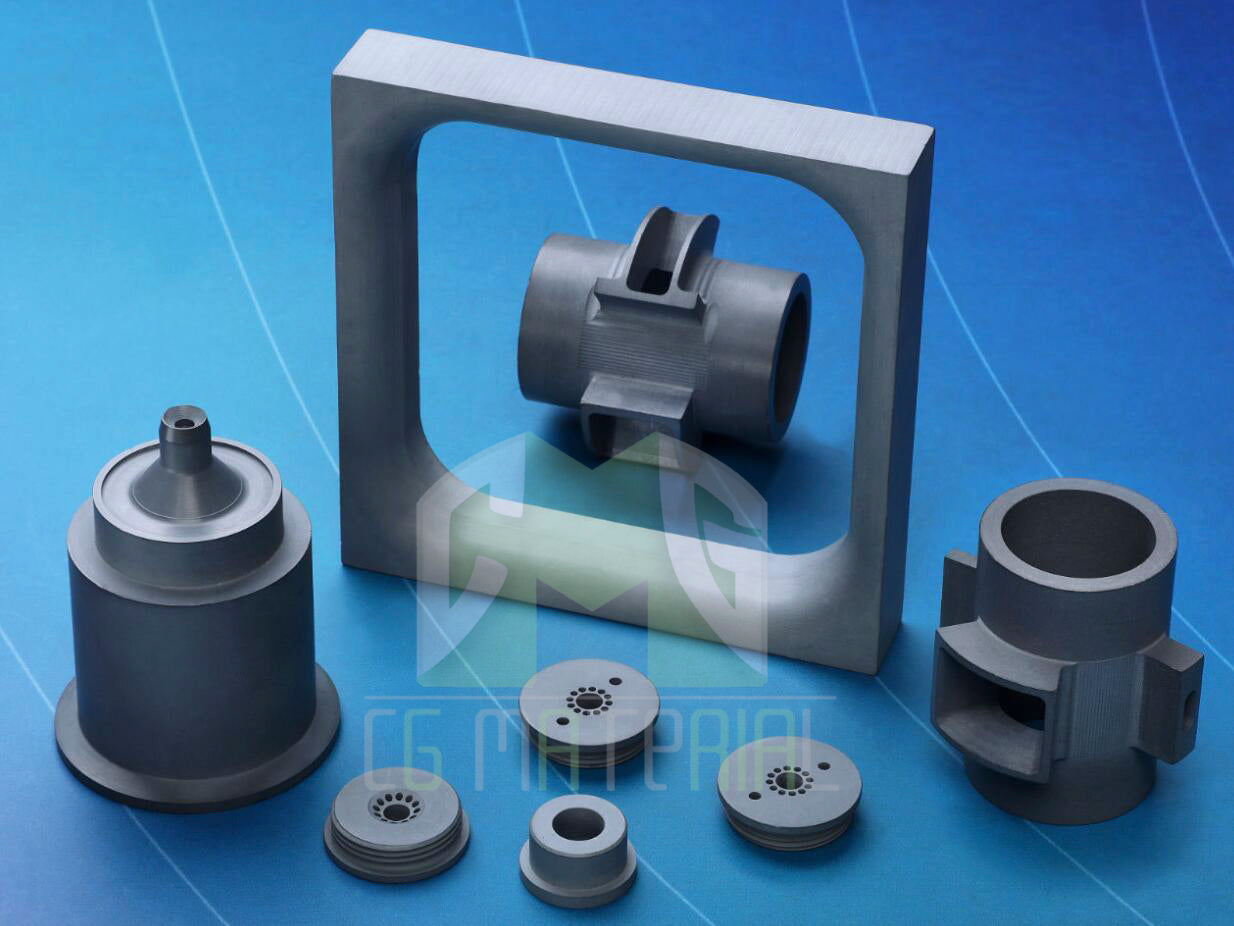

Boron Nitride (BN) custom machined parts are specially designed components made from high-purity boron nitride material. They are known for their excellent thermal and electrical insulation properties, high-temperature resistance, and exceptional chemical inertness.

BN custom machined parts can be produced in a variety of shapes, sizes, and configurations to suit specific industrial and research applications. Some common BN custom machined parts include insulators, heating elements, crucibles, thermocouple sheaths, and reaction vessels.

These parts are made using a variety of precision machining processes, such as diamond grinding, laser cutting, and waterjet cutting. The high purity of the boron nitride material ensures that the machined parts are free from impurities, making them ideal for use in demanding applications that require high thermal and electrical stability.

Some key benefits of using boron nitride custom machined parts include:

-

High thermal conductivity: BN custom machined parts are excellent heat conductors, making them ideal for use in high-temperature applications.

-

Excellent chemical inertness: BN material is highly resistant to chemical attack, making it suitable for use in harsh chemical environments.

-

Electrical insulation: BN material has excellent electrical insulation properties, making it ideal for use in electrical components and insulators.

-

Low coefficient of thermal expansion: BN material has a low coefficient of thermal expansion, which makes it ideal for use in applications that require stable dimensions across a wide temperature range.

Overall, boron nitride custom machined parts are a versatile and high-performance solution for a wide range of industrial and research applications that require exceptional thermal, electrical, and chemical properties.

Boron Nitride Ceramics Specification

CG Material production formulations are developed to address the varied application problems in which ceramic components are commonly used. Many industrial applications push the envelope on specific requirements leading to the development of new formulations to successfully address them.

| Item No. | Description | Purity | Lot Size |

| CG-NI05-98 | Boron Nitride Powder Particle Size: 3 µm, 200 mesh or 325mesh |

BN > 98 %, B2O3 < 0.6%, Ca < 0.015%, Si < 0.12% |

100 kg 1000kg Customize |

| CG-NI05-99 | Boron Nitride Powder Particle Size: 3 µm, 200 mesh or 325mesh |

BN > 99 %, B2O3 < 0.4%, Ca < 0.01%, Si < 0.10% |

100 kg 1000kg Customize |

Comparison of Boron Nitride Ceramics

| Grade | BN-BO | BN-SZ | BN-AlN |

| Compositions | BN>98% | BN+SiC+ZrO2 | BN+AIN |

| Binder | B2O3 | / | AlBO3 |

| Density | 2.1-2.2 g/cm3 | 2.3-3.0 g/cm3 | 2.5-2.6 g/cm3 |

| 25°C Volume Resistivity | >1013 Ω·cm | >1012 Ω·cm | >1014 Ω·cm |

| Max. Service Temp. (°C) Oxygen; Inert Gas; High Vacuum |

900 2000 1800 |

900 1700 1700 |

900 2100 1900 |

| Flexural Strength | 75 Mpa | 100 Mpa | 130 Mpa |

| Compressive Strength | 100 Mpa | 300 Mpa | 250 Mpa |

| Coefficient of Thermal Expansion 25-1000°C |

2.0 x 10–6/K | 4.0 x 10–6/K | 4.5 x 10–6/K |

| Thermal Conductivity | 30 W/mK | 40 W/mK | 60 W/mK |

Boron Nitride Custom Parts Applications

– Boron Nitride parts for ion injection equipment

– Electric insulators in vacuum system

– Spacers for glass melting

– Feed through for high voltage equipment

– Boron Nitride components for PVD, MOCVD, MBE system.

Boron Nitride Custom Parts Available Materials

| Material | Description | Availability |

| BN99 | Hot pressed at high temperature (1900℃). Excellent corrosion resistance and thermal conductivity. Limited wear resistance Self-bonded and high purity(>99%) |

Machinable Blanks Finished Parts |

| BNBO | General purpose material Bonded by boric oxide |

Finished Parts |

| BNCB | Calcium borate bonded boron nitride Enhanced moisture resistance |

Finished Parts |

| BN60 | BN 60%, SiO2 40% | Finished Parts |

| BN40 | BN 40%, SiO2 60% | Finished Parts |

| ZSBN | BN-45%, Zr2O3 45% | Finished Parts |

Packaging

We handle our products with care to ensure they remain in their original condition during storage and transportation and to preserve their quality.