CG MATERIAL

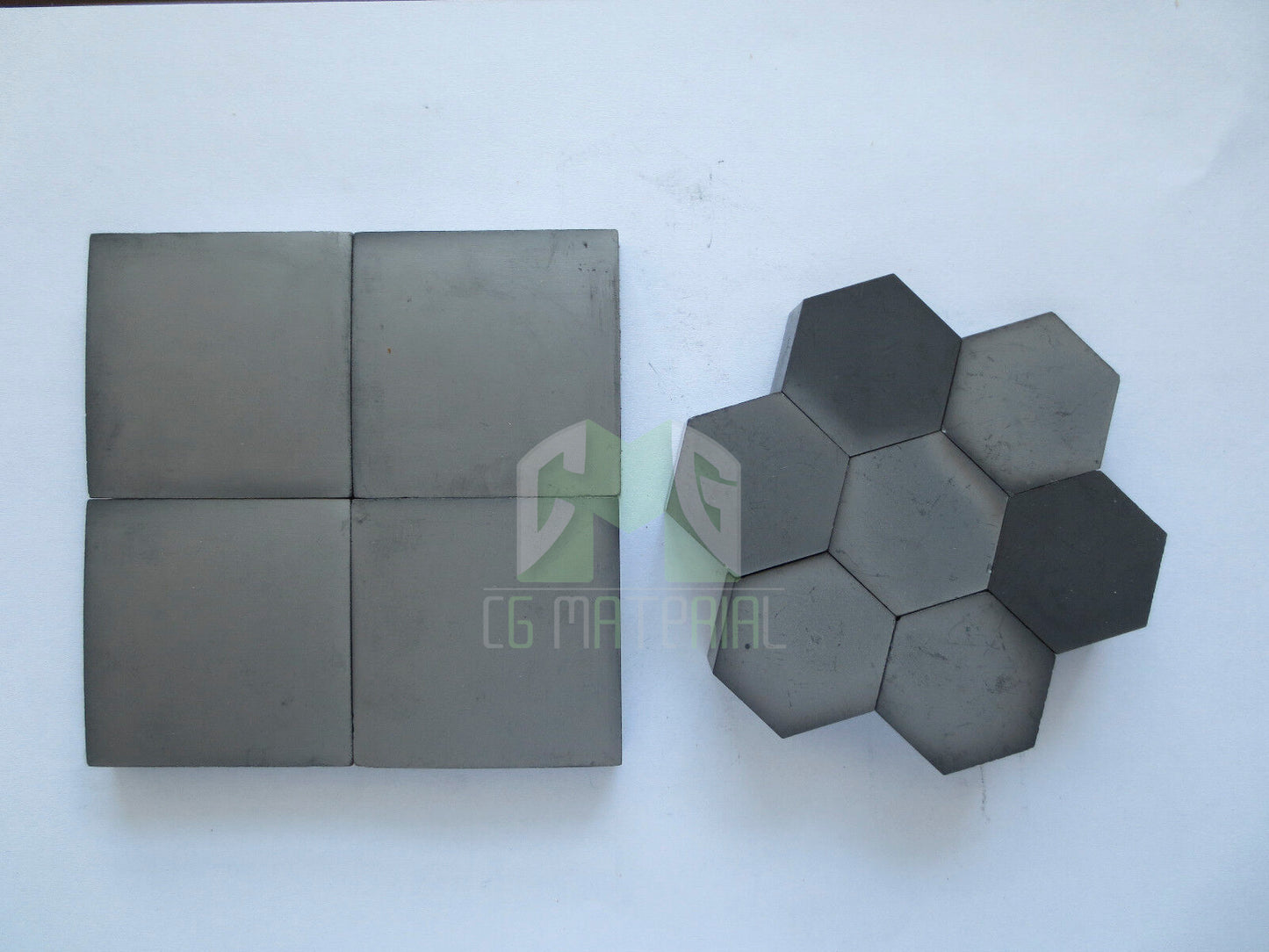

Boron Carbide Plate, B4C Plate

Boron Carbide Plate, B4C Plate

Boron carbide plate, also known as B4C plate, is a ceramic material that consists of boron carbide and a small amount of carbon. It is one of the hardest materials known, with a Mohs hardness rating of 9.3, which is just below that of diamond. Boron carbide plates are commonly used in armor applications due to their high hardness and excellent ballistic performance.

Boron carbide plates are lightweight and have excellent strength and durability, making them suitable for use in various applications such as ballistic armor, wear-resistant coatings, and cutting tools. They are also resistant to high temperatures and are often used in nuclear applications and as neutron absorbers.

Boron carbide plates are typically fabricated using a hot-pressing method, which involves the application of high temperature and pressure to form a dense and uniform material. The resulting boron carbide plates have high density, high strength, and excellent hardness, making them suitable for use in extreme environments.

Boron Carbide Ceramics Specification

| Item No. | Description | Purity | Lot Size |

| CG-CB05-100M | Boron Carbide Powder Particle Size: 100 mesh |

Total B > 78 %, Total C > 19% B2O3 < 0.15%, Free B < 0.3%, Free C < 2.5% |

100 kg 500 kg 1,000 kg Customize |

| CG-CB05-325M | Boron Carbide Powder Particle Size: 325 mesh |

Total B > 78 %, Total C > 19% B2O3 < 0.15%, Free B < 0.3%, Free C < 2.5% |

100 kg 500 kg 1,000 kg Customize |

| CG-CB05-1000 | Boron Carbide Powder Particle Size:1000 Grit |

Total B > 78 %, Total C > 19% B4C > 95% B2O3 < 0.15%, Fe < 0.2% |

100 kg 500 kg 1,000 kg Customize |

| CG-CB05-1200 | Boron Carbide Powder Particle Size:1200 Grit |

Total B > 78 %, Total C > 19% B4C > 95% B2O3 < 0.15%, Fe < 0.2% |

100 kg 500 kg 1,000 kg Customize |

Boron Carbide Ceramic Applications

Boron carbide ceramics are applied widely in industries as wearing resistant materials, and abrasives. As an abrasive, it is used in powdered form in the lapping (fine abrading) of metal and ceramic products, though its low oxidation temperature of 400–500° C (750–930° F) makes it unable to withstand the heat of grinding hardened tool steels.

Because of its hardness, together with its very low density, it has found application as a reinforcing agent for aluminum in military armor and high-performance bicycles, and its wear resistance has caused it to be employed in sandblasting nozzles and pump seals.

Its ability to absorb neutrons without forming long-lived radionuclides makes it attractive as an absorbent for neutron radiation arising in nuclear power plants and from anti-personnel neutron bombs. Nuclear applications of boron carbide include shielding, control rod and shut down pellets. Within control rods, boron carbide is often powdered, to increase its surface area.

Boron Carbide Plate Properties

| Compound Formula | B4C |

| Molecular Weight | 55.26 |

| Appearance | Black |

| Melting Point | 2445℃ |

| Density | 2.1 to 2.7 g/cm3 |

| Electrical Resistivity | 0 to 11 10x Ω-m |

| Poisson's Ratio | 0.17-0.18 |

| Specific Heat | 950 J/kg-K |

| Tensile Strength | 350 MPa (Ultimate) |

| Thermal Conductivity | 31 to 90 W/m-K |

| Thermal Expansion | 4.5 to 5.6 µm/m-K |

Boron Carbide Plate Applications

Abrasive field :

Surfaces of watches and jewels.

Refractory materials :

As an antioxidant additives in refractory field.

Ceramics materials :

As materials made of boron carbide products and wear resistant components using in Blasting , Sealing , Machinery , Ships , Auto , Dies , Aviation and Aerospace industries.

Armor tiles :

High density boron carbide armor tiles , bullet proofing seats of helicopters.

Nuclear industry :

Boron carbide is an important material for nuclear applications due to high absorption cross section.

Boriding Agent :

Boron carbide is a raw material used in boriding agent. After the treatment, the hardness and the wear resistance of the surface are greatly improved.

Chemical additives :

Because of its good chemical resistance, it can be used for producing other boron containing materials such as titanium boride or zirconium boride.

Solid fuel :

Boron carbide based propellants for ducted rockets.

Packaging

We handle our products with care to ensure they remain in their original condition during storage and transportation and to preserve their quality.