CG MATERIAL

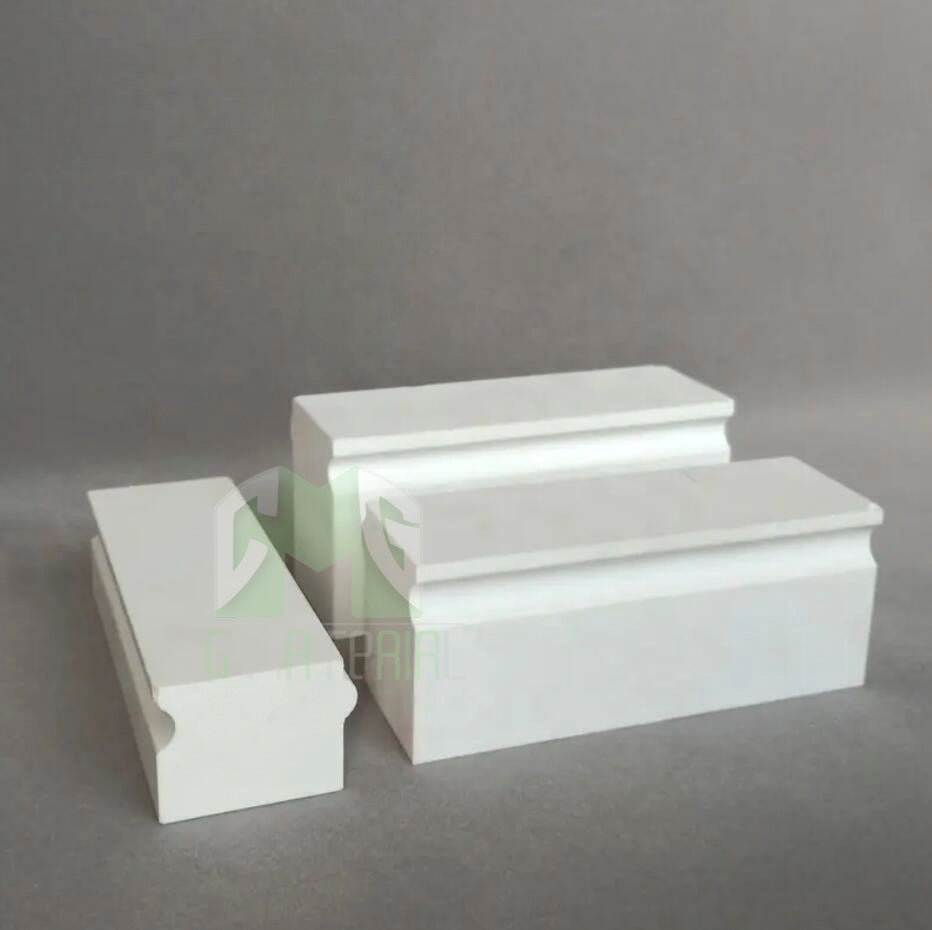

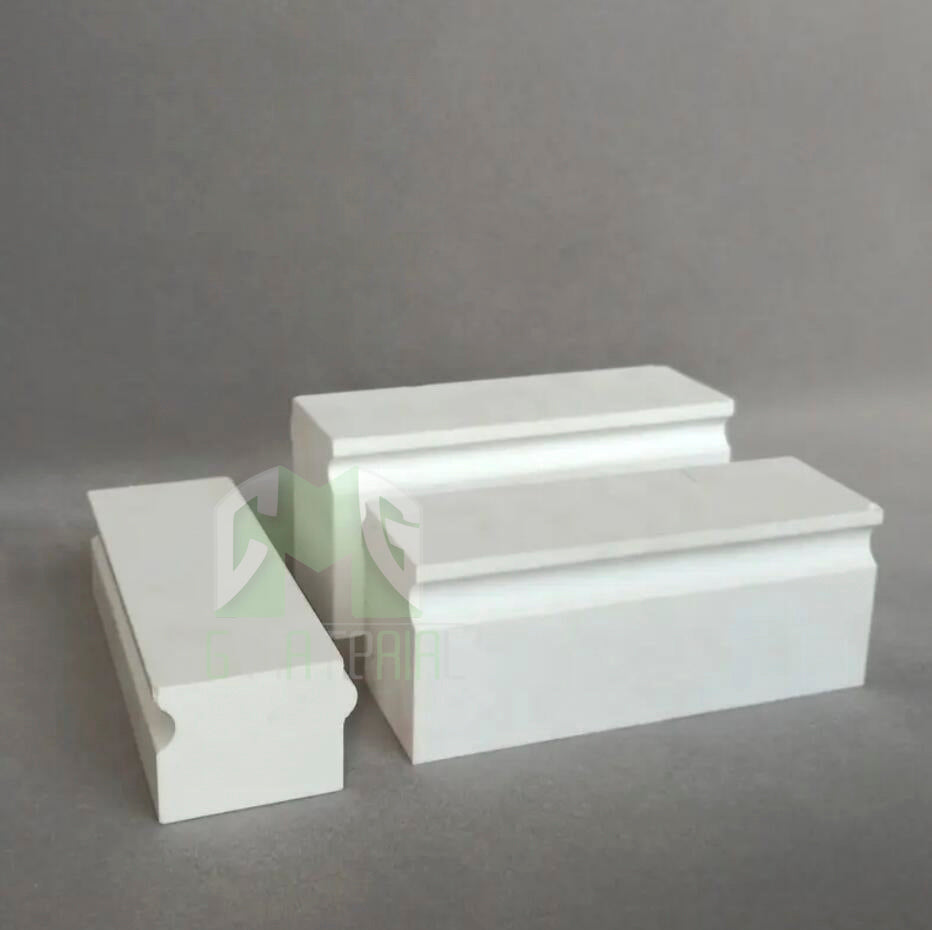

Alumina Lining Brick

Alumina Lining Brick

Alumina lining bricks are high-density, high-alumina refractory products made from alumina powder and other additives. They are commonly used to line the interior walls of ball mills and other grinding equipment to protect them from abrasion and erosion.

Alumina lining bricks have high mechanical strength and excellent resistance to wear, corrosion, and high temperatures. They are suitable for use in a variety of industries, including ceramics, cement, mining, and metallurgy.

The properties of alumina lining bricks can be customized to meet the specific needs of each application. Different formulations can be used to achieve varying levels of wear resistance, density, and thermal conductivity.

In addition to their use as lining materials, alumina bricks can also be used as insulation materials in high-temperature furnaces and kilns. Their thermal stability and low thermal conductivity make them effective insulation materials, particularly in applications where space is limited.

Overall, alumina lining bricks are a reliable and effective solution for protecting grinding equipment from wear and erosion. Their high performance and versatility make them a popular choice in a wide range of industrial applications.

| Catalog No. | CERAMICS |

|---|---|

| Size | Customized |

| Material | Al2O3 |

| Purity | 95% 99% 99.7% |

| Density | 3.8~3.9 g/cm3 |

At CG Material, we offer high quality Alumina Lining Brick with exceptional purity and precision in terms of size. Our products range in diameter from 1mm to 100mm and have a purity level of up to 99.8%. We also provide custom manufacturing options for special shapes to meet specific needs.

Alumina Lining Brick Specifications

Alumina lining brick products have the characteristics of high hardness, high density, low abrasion, good regularity, and corrosion resistance. Alumina bricks are used for wear-resistant linings of ball mills. Wear-resistant Alumina ceramic lining bricks can increase the service life of ball mill linings. Alumina grinding bricks can increase grinding space, and grinding efficiency, raise output by 30%-50% and reduce grinding time.

| Property | Value |

| Al2O3(%) | >92 |

| Bulk Density (g/cm3) | >3.6 |

| Hardness (mohs) | 9 |

| Wear Loss(%) | <0> |

| Color | White |

Alumina Lining Brick Features

-High mechanical strength

-Excellent abrasion

-Excellent impact resistance

-Corrosion and chemical resistance

-Lightweight

Alumina Lining Brick Applications

Utilized in industries such as pharmaceutics, cement, paint/pigments, chemicals, and coating, ceramic alumina lining bricks have a positive impact on the grinding process and production costs, and they’re good for the environment as they lessen the usage of power and pollution. And it is widely used in ball mills and pipelines as wear-resistance lining.

Packaging

We handle our products with care to ensure they remain in their original condition during storage and transportation and to preserve their quality.